Skills Needs in Manufacturing, Tables

see Related Article

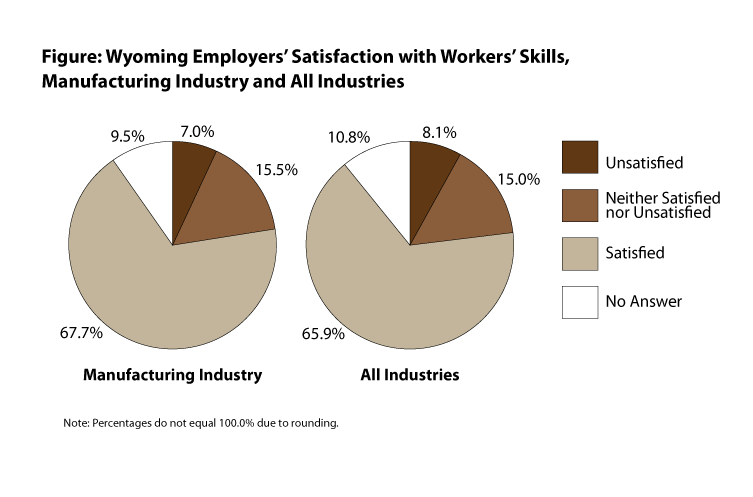

Figure: Figure

| Skill | Definition |

|---|---|

| Active learning | Understanding the implications of new information for both current and future problem-solving and decision-making. |

| Active listening | Giving full attention to what other people are saying, taking time to understand the points being made, asking questions as appropriate, and not interrupting at inappropriate times. |

| Complex problem solving | Identifying complex problems and reviewing related information to develop and evaluate options and implement solutions. |

| Coordination | Adjusting actions in relation to others' actions. |

| Critical thinking | Using logic and reasoning to identify the strengths and weaknesses of alternative solutions, conclusions or approaches to problems. |

| Equipment maintenance | Performing routine maintenance on equipment and determining when and what kind of maintenance is needed; included with operation and control. |

| Equipment selection | Determining the kind of tools and equipment needed to do a job; included with operation and control. |

| Installation | Installing equipment, machines, wiring, or programs to meet specifications. |

| Instructing | Teaching others how to do something. |

| Judgment and decision making | Considering the relative costs and benefits of potential actions to choose the most appropriate one. |

| Learning strategies | Selecting and using training/instructional methods and procedures appropriate for the situation when learning or teaching new things; included with critical thinking. |

| Management of financial resources | Determining how money will be spent to get the work done, and accounting for these expenditures; included with management of material resources. |

| Management of material resources | Obtaining and seeing to the appropriate use of equipment, facilities, and materials needed to do certain work. |

| Management of personnel resources | Motivating, developing, and directing people as they work, identifying the best people for the job; included with management of material resources. |

| Mathematics | Using mathematics to solve problems. |

| Monitoring | Monitoring/assessing performance of yourself, other individuals, or organizations to make improvements or take corrective action; included with critical thinking. |

| Negotiation | Bringing others together and trying to reconcile differences. |

| Operation and control | Controlling operations of equipment or systems. |

| Operation monitoring | Watching gauges, dials, or other indicators to make sure a machine is working properly; included with operation and control. |

| Operations analysis | Analyzing needs and product requirements to create a design; included with critical thinking |

| Persuasion | Persuading others to change their minds or behavior. |

| Programming | Writing computer programs for various purposes; included with critical thinking. |

| Quality control analysis | Conducting tests and inspections of products, services, or processes to evaluate quality or performance; included with critical thinking. |

| Reading comprehension | Understanding written sentences and paragraphs in work-related documents. |

| Repairing | Repairing machines or systems using the needed tools. |

| Science | Using scientific rules and methods to solve problems. |

| Service orientation | Actively looking for ways to help people. |

| Social perceptiveness | Being aware of others' reactions and understanding why they react as they do. |

| Speaking | Talking to others to convey information effectively. |

| Systems analysis | Determining how a system should work and how changes in conditions, operations, and the environment will affect outcomes; included with critical thinking. |

| Systems evaluation | Identifying measures or indicators of system performance and the actions needed to improve or correct performance, relative to the goals of the system. |

| Technology design | Generating or adapting equipment and technology to serve user needs. |

| Time management | Managing one's own time and the time of others. |

| Troubleshooting | Determining causes of operating errors and deciding what to do about it. |

| Writing | Communicating effectively in writing as appropriate for the needs of the audience. |

| Adapted from O*NET OnLine, http://www.onetonline.org/find/descriptor/browse/Skills/ | |

Operation and Control |

|||

| Skills | Manufacturing | All Industries | |

|---|---|---|---|

| Reported as Important | N | 449 | 6,954 |

| Row % | 6.4% | 100.0% | |

| Col % | 79.4% | 63.0% | |

| Not Reported as Important | N | 116 | 4,075 |

| Row % | 2.8% | 100.0% | |

| Col % | 20.5% | 36.9% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Reading Comprehension |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 385 | 7,558 |

| Row % | 5.0% | 100.0% | |

| Col % | 68.1% | 68.5% | |

| Not Reported as Important | N | 180 | 3,471 |

| Row % | 5.1% | 100.0% | |

| Col % | 31.8% | 31.4% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Critical Thinking |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 481 | 8,766 |

| Row % | 5.4% | 100.0% | |

| Col % | 85.1% | 79.4% | |

| Not Reported as Important | N | 84 | 2,263 |

| Row % | 3.7% | 100.0% | |

| Col % | 14.8% | 20.5% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Technology Design |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 290 | 4,365 |

| Row % | 6.6% | 100.0% | |

| Col % | 51.3% | 39.5% | |

| Not Reported as Important | N | 275 | 6,664 |

| Row % | 4.1% | 100.0% | |

| Col % | 48.6% | 60.4% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Service Orientation |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 292 | 8,028 |

| Row % | 3.6% | 100.0% | |

| Col % | 51.6% | 72.7% | |

| Not Reported as Important | N | 273 | 3,001 |

| Row % | 9.0% | 100.0% | |

| Col % | 48.3% | 27.2% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Installation |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 59 | 514 |

| Row % | 11.4% | 100.0% | |

| Col % | 10.4% | 4.6% | |

| Not Reported as Important | N | 506 | 10,515 |

| Row % | 4.8% | 100.0% | |

| Col % | 89.5% | 95.3% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Active Listening |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 33 | 484 |

| Row % | 6.8% | 100.0% | |

| Col % | 5.8% | 4.3% | |

| Not Reported as Important | N | 532 | 10,545 |

| Row % | 5.0% | 100.0% | |

| Col % | 94.1% | 95.6% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Mathematics |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 6 | 107 |

| Row % | 5.6% | 100.0% | |

| Col % | 1.0% | 0.9% | |

| Not Reported as Important | N | 559 | 10,922 |

| Row % | 5.1% | 100.0% | |

| Col % | 98.9% | 99.0% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Time Management |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 7 | 155 |

| Row % | 4.5% | 100.0% | |

| Col % | 1.2% | 1.4% | |

| Not Reported as Important | N | 558 | 10,874 |

| Row % | 5.1% | 100.0% | |

| Col % | 98.7% | 98.5% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Active Learning |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 11 | 92 |

| Row % | 11.9% | 100.0% | |

| Col % | 1.9% | 0.8% | |

| Not Reported as Important | N | 554 | 10,937 |

| Row % | 5.0% | 100.0% | |

| Col % | 98.0% | 99.1% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

Management of Material Resources |

|||

| Skills | Manufacturing | All Industries | |

| Reported as Important | N | 6 | 129 |

| Row % | 4.6% | 100.0% | |

| Col % | 1.0% | 1.1% | |

| Not Reported as Important | N | 559 | 10,900 |

| Row % | 5.1% | 100.0% | |

| Col % | 98.9% | 98.8% | |

| Total | N | 565 | 11,029 |

| Row % | 5.1% | 100.0% | |

| Col % | 100.0% | 100.0% | |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||